-

Modular Design, Easily scalable to accommodate growing production needs, from 1,000 LPH to 50,000 LPH and beyond.

-

Automation & Control, Integrated PLC + HMI touchscreen controls allow easy parameter adjustments, alarms, batch tracking, and performance analytics.

-

Energy Efficiency, Advanced heat recovery units and frequency-driven pumps reduce energy consumption and carbon footprint.

-

High Sanitation Standards,All components are made from food-grade SUS304 or SUS316L, with sanitary welds, polished surfaces, and FDA-approved gaskets.

-

Flexible Configuration, Whether you're processing cow milk, buffalo milk, or goat milk, our systems can be adjusted for viscosity, temperature range, and microbial load.

-

CIP , All systems support full Clean-in-Place (CIP) integration, ensuring minimal downtime, maximum hygiene, and simplified daily maintenance.

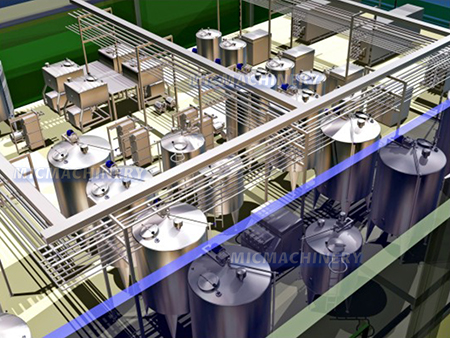

Dairy Products Machinery

BRIEF INTRODUCTION

▻▻▻▻▻ Customizable for:

〇 Pasteurized milk

〇 UHT milk〇 Flavored milk

〇 Condensed milk

〇 Milk powder

〇 Yogurt & probiotic drinks〇 Cream & fermented milk

〇 Cheese

Step-by-Step Dairy Processing Line Installation

1)Milk Reception & Storage

Raw milk is received through insulated stainless-steel tanks equipped with flow meters, sampling valves, and cooling systems. Initial quality checks are performed to ensure safety and compliance.

2)Clarification & Standardization

The milk passes through centrifugal clarifiers to remove dirt, somatic cells, and air. Standardization units then adjust fat content to the desired level, preparing the milk for pasteurization.

3)Pasteurization or UHT Treatment

Depending on the product line, HTST or UHT systems are installed. Our pasteurizers offer precise temperature control, energy recovery modules, and safety interlocks to ensure consistent results.4)Homogenization & Cooling

High-pressure homogenizers reduce fat globules to enhance texture and stability. Cooling systems immediately bring the milk to packaging-ready temperatures to preserve flavor and freshness.

5)Fermentation & Flavor Integration (for yogurt/flavored milk)

Controlled fermentation tanks manage pH and temperature to produce consistent fermented milk products. Mixers and flavor dosing units are added for flavored milk lines.

6)Filling, Packaging & Labeling

Automated filling machines, labeling systems, and packaging modules complete the line, ensuring high output with minimal operator intervention.7)Clean-in-Place (CIP) System

The fully automated CIP system ensures hygienic cleaning of the entire process line, reducing downtime and contamination risks. It includes acid, alkaline, and hot water cycles.

Engineering Advantages of Mic Machinery Lines

Complete Project Support from Concept to Commissioning

Understanding client goals, product type, volume requirements, and factory conditions.

● Custom Line Design

Creating detailed P&ID, layout plans, and equipment selection with CAD simulations.

● Manufacturing & Assembly

All machines are fabricated and tested in our factory to reduce installation time onsite.

● Installation & Commissioning

Engineers install, connect, and calibrate every component of the line. Commissioning includes FAT (Factory Acceptance Test) and SAT (Site Acceptance Test).

● Training & Documentation

On-site training for operators and maintenance staff, plus full technical manuals.

This end-to-end service model reduces risk, avoids communication delays, and speeds up plant launch.

Certifications, Quality Standards & Materials

➢ Quality Materials

All wetted parts are constructed from SUS304 or SUS316L stainless steel. Surface finishes reach Ra < 0.8μm for hygiene.➢ Standards & Certifications

We comply with ISO 9001, CE, GMP, and FDA standards. Pressure vessels and pasteurizers are certified per PED or ASME requirements where applicable.➢ Precision Fabrication

Laser cutting, orbital welding, and TIG welding ensure perfect joints and long-lasting performance.➢ Testing & Validation

Each component undergoes pressure, flow, temperature, and durability testing before delivery.These practices position Mic Machinery as one of the most reliable milk treatment equipment for dairy factories suppliers globally.

Global Reach with Strong After-Sales Support

● Spare parts kits for critical wear components

● Remote troubleshooting via PLC/SCADA integration

● Online and on-site support

● Annual maintenance packages (optional)

Our reputation is built on trust, performance, and support—ensuring your plant operates smoothly long after installation.

Build Your Modern Dairy Line with Mic Machinery

From energy-saving processing modules to intelligent automation, our systems meet the strictest health and quality regulations. Join the growing list of producers that trust Mic Machinery for reliable, scalable, and sustainable dairy production.

- Hot Sauce Filling Production Line

- Lube Oil Production Line

- Olive Oil Production Line

- Perfume Production Line

- Silicone Production Line

- Beer Production Line

- Tube Manufacturing Machine

- Filling Machine Manufacturer

- Visual Inspection Machine

- Bottle Blowing Machine

- Laser Coding Machine

- Aseptic Cold Filling Machine

- Fruit and Vegetable Processing Machinery Manufacturer

- Dairy Products Machinery

- Alcoholic Drink Production Equipment

- Commercial Water Treatment System